Increase in risks calls for more resilient supply chains

09/12/22

A better balance between efficiency and resilience

Global disruption is increasingly forcing companies to look at the resilience of their supply chains. The unpredictability in the world and the increase in risks make it all the more important for companies to be able to move quickly in their supply chains in order to maintain their production and distribution in the best possible way. For this, transparency in the chain is a prerequisite, Rolf Bos cites as one of the conclusions in the PwC report 'Rebuilding supply chains'.

In the report, PwC examines trends in global supply chains and the changes that are expected to be permanent in the near future. The analysis highlights vulnerabilities in supply chains across industries. A key finding is that almost every sector in the very open Dutch economy faces disruptions and pressures, but the causes are different.

'Some sectors suffer a lot from high transport costs, others more from high energy prices. And yet other sectors depend heavily on the availability of qualified staff,' says Bos, who works at PwC in the 'Operations' team.

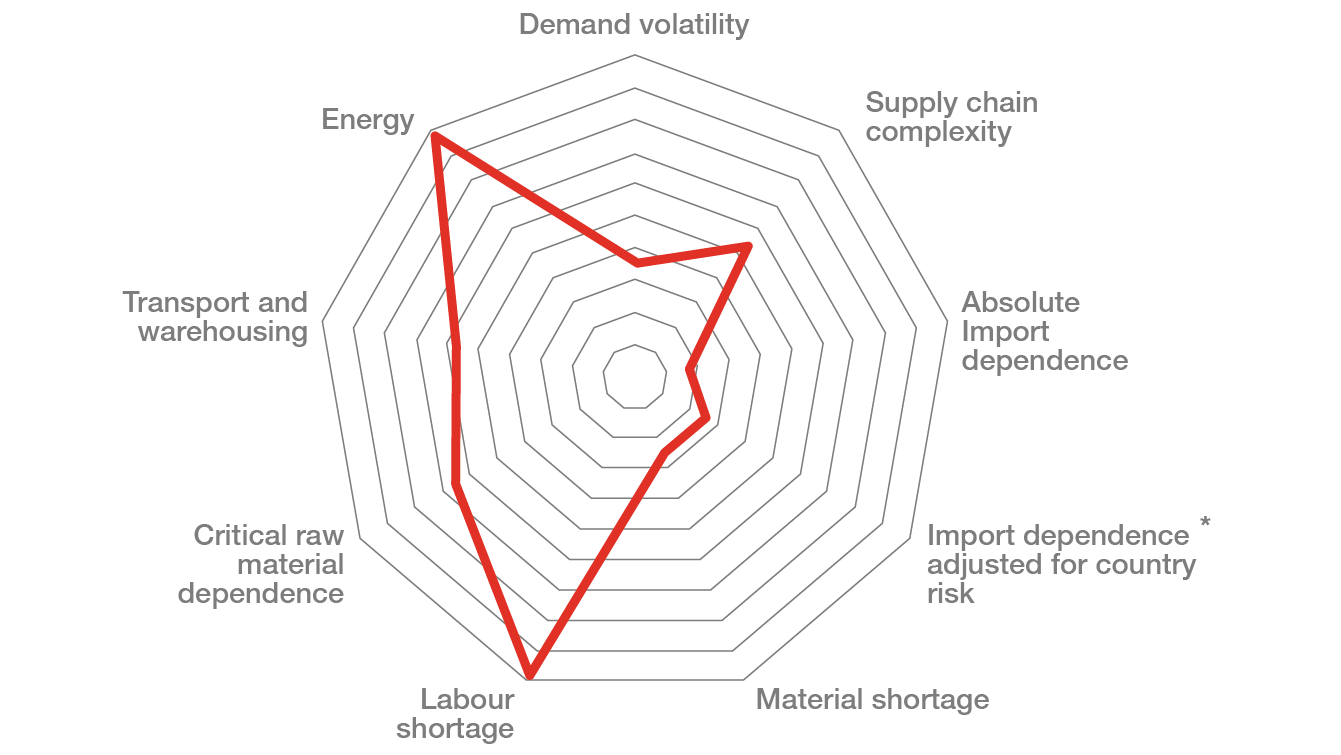

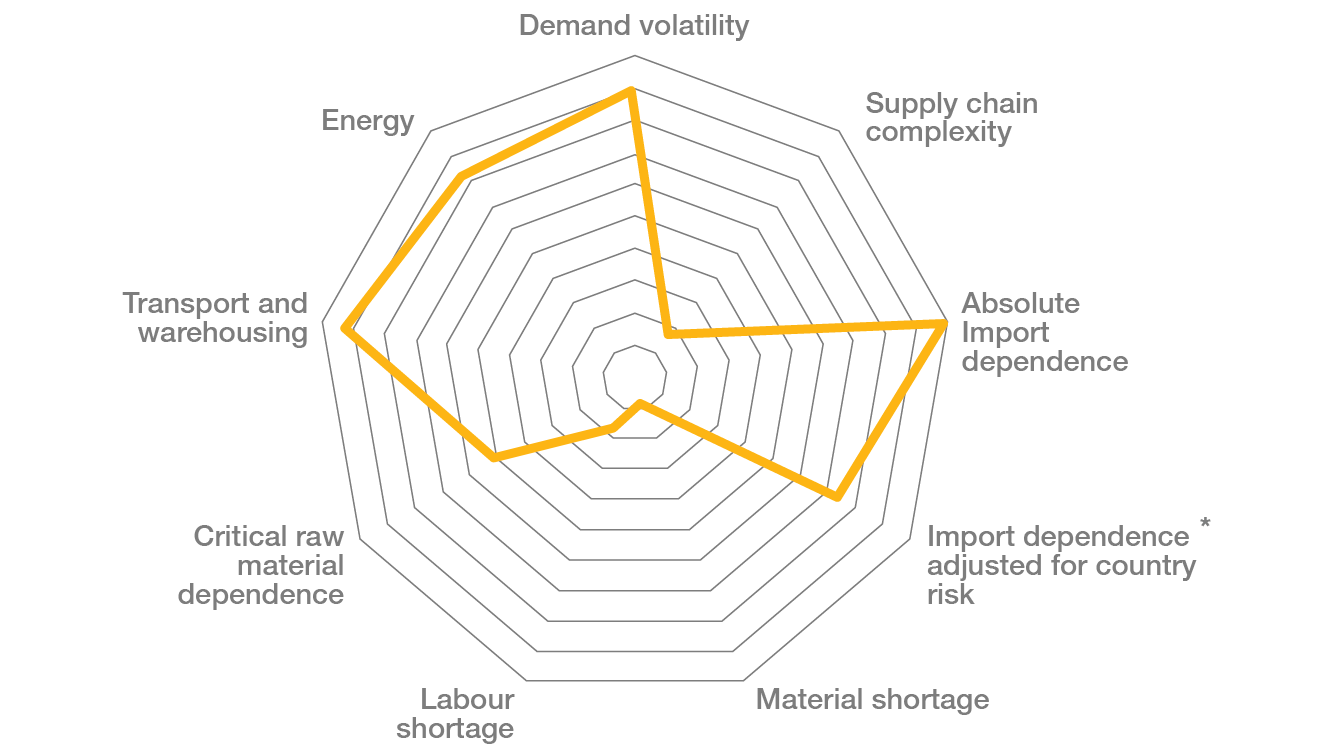

Vulnerabilities per industry

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

*Import dependence adjusted for political and climate risk in country that the imports come from

Efficiency was most important in supply chains for years

According to Bos, keeping supply chains profitable has changed a lot in a short time. This is mainly due to the changed relationships in the world. 'When it came to their supply chains, companies mainly looked at efficiency for years. Logical, as efficiency means effective production and distribution, and low costs. But since the Covid-19 pandemic, things have changed'.

'The corona outbreak disrupted many supply chains and delayed the delivery of a large number of products. Most companies proved unable to adapt to that quickly, but assumed that after the pandemic, everything would go back to business as usual. So that is not the situation.'

No incidents, but structural disruptions

'With the growth of global trade and global dependencies, and the increasing complexity of supply chains, the impact of disruptions is greater than before. You can no longer speak of incidents. The world has become more unpredictable and risky. Think of the conflict in Ukraine, but also of major natural disasters. On top of that, companies increasingly have to comply with ESG guidelines. This means, for instance, that companies have to be aware of working conditions not only at their direct suppliers, but also at the suppliers of those companies.'

For companies, this implies looking much more at the resilience and flexibility of their supply chains. Bos: 'But that is not so simple. After all, there is no "one-size-fits-all" approach. And it often comes with quite a price tag.'

Balancing efficiency and resilience

To find a better balance between efficiency and resilience in their supply chains, companies would do well to address the following points:

Ensure greater transparency and alignment with business partners

Companies looking to rebalance between efficiency and resilience need visibility and alignment across their supply chains. Companies often have no visibility into their suppliers' suppliers and therefore cannot identify their risks. Or they do not integrate well enough with their business partners and, partly as a result, cannot adapt quickly enough to new and emerging trends.

Reduce unnecessary complexity to reduce risk

A company's offering is often diverse and therefore complex. On the one hand, this complexity creates a competitive advantage through, among other things, a better customer experience. At the same time, companies are generally stuck with unnecessary products, suppliers and customer portfolios that have grown historically and do not add value. By segmenting and reducing unnecessary complexity, a company reduces its exposure to unnecessary risks.

Bring diversification to supply chain

To reduce exposure to risk, companies should also focus on diversifying their suppliers. This diversification can be in the number of suppliers, but also in the geographical spread or distance of suppliers. A third possible sourcing strategy is so-called vertical integration. This is taking over suppliers or producing the supplied products itself, giving a company a better view of the supply chain and making it less dependent on other parties.

Rethink operational strategies

Several improvement opportunities exist within operations to prevent or at least mitigate supply chain disruptions. Consider new pricing strategies, changes in inventory management and the use of risk models and predictive data analytics.

Evaluate the maturity of existing processes

In a mature process, supply chain management and risk management go hand in hand and complement each other. A clear and effective governance model is therefore a prerequisite for effective risk management.